Views: 16 Author: Site Editor Publish Time: 2022-06-21 Origin: Site

Many friends who want to buy an engraving machine are confused about this. In fact, the generalized CNC engraving machine includes a laser engraving machine, which can be equipped with a laser head for engraving. The laser engraving machine can also be a CNC engraving machine. Therefore, the two intersect, there is an intersection relationship, but there are also many differences.

What is Laser engravers ?

Metal engraving machineare the best systems to engrave MDF, acrylic, paper, fabric, leather and much more. The machine uses the laser as an engraving tool and Co2 as a laser source, to produce a permanent, crisp and a highly detailed mark without actually touching the material. As compared to the traditional methods, laser engraving is a fast process enabling the user to engrave even the most complex designs with so much ease!

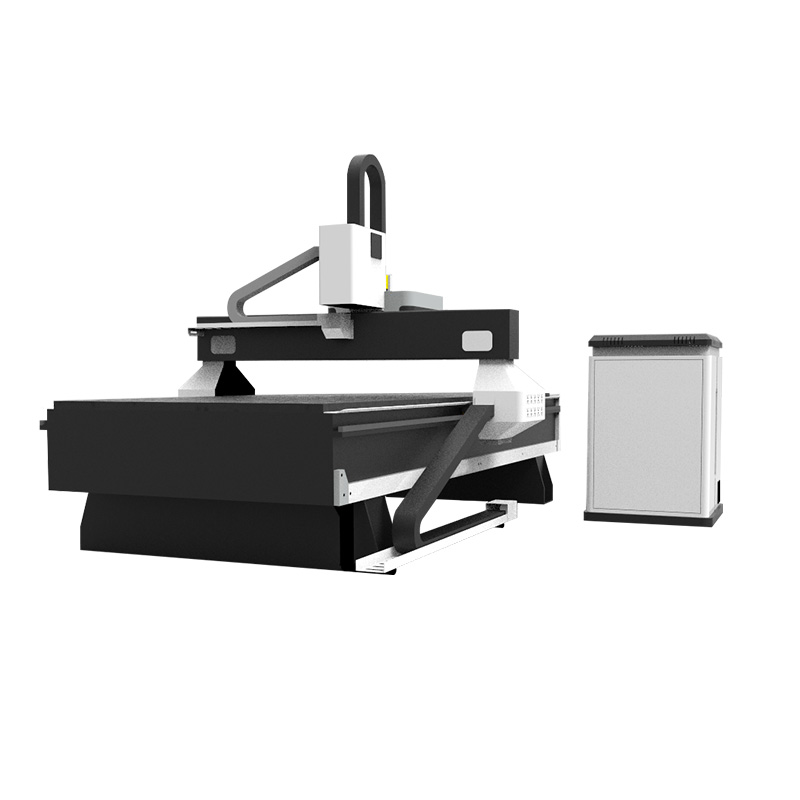

What is CNC Engraving?

Engraving is a cutting technique or process of carving a design into a hard surface, to decorate or label on the objects made of different materials, typically using a set of hand engraving tools in the past, but CNC engraving is also available now. wood engraving router uses computer-controlled machines, which often applies the milling paths generated by CAD-CAM software based on the design drawing. Compared to manual engraving machines, CNC engraving machines, which reduces errors and improves speed, have the capability to do various sophisticated precision engraving, whether for practical or artistic purposes.

1. Different working principles

Laser engraving machine is a kind of equipment that uses the heat energy of laser to engrave materials. The laser light is emitted by a laser and is focused into a high-power density laser beam through the optical path system. The light energy of the laser beam causes chemical and physical changes in the surface material to engrave traces, or light energy burns off part of the material to display patterns and texts that need to be etched.

CNC engraving machine relies on a high-speed rotating engraving head driven by an electric spindle. Through the tool configured according to the processing material, the processing material fixed on the host table can be cut, and various flat or three-dimensional patterns designed by the computer can be carved. The embossed graphics and text can realize automatic engraving operation.

2. the mechanical structure is different

Laser engraving machines can be divided into different types of special machines according to their specific uses. The structure of these dedicated machines is roughly the same. For example: the laser source emits the laser, the numerical control system controls the stepping motor, and the focus is moved on the X, Y, and Z axes of the machine tool through optical elements such as the laser head, reflector, and lens, thereby ablating the material for engraving.

The structure of CNC engraving machine is relatively simple. It is controlled by a computer numerical control system, so that the engraving machine automatically selects the appropriate engraving tool to engrave on the X, Y, and Z axes of the machine tool.

In addition, the cutter of the laser engraving machine is a complete set of optical components. The tools of the CNC engraving machine are engraving tools of various entities.

3.the processing accuracy is different

The diameter of the laser beam is only 0.01mm. The laser beam can carry out smooth and bright engraving and cutting in narrow and delicate parts. However, the CNC tool is not very helpful, because the diameter of the CNC tool is 20 times larger than the laser beam, so the processing accuracy of the CNC engraving machine is not as good as the laser engraving machine.

4. Different processing efficiency

The laser speed is fast, the laser is 2.5 times the speed of the CNC engraving machine. Because laser engraving and polishing can be done at one time, CNC needs to be done in two parts. Moreover, the energy consumption of laser engraving machine is less than that of CNC engraving machine.

5. Other differences

Laser engraving machine is noiseless, pollution-free and efficient; CNC engraving machine is relatively noisy and pollutes the environment.

CNC engraving machine is more and more popular, we all find it brings convenience, so CNC engraving machine has what advantages, let us have a look.

1, Versatile: A CNC engraving machine can work on a variety of materials with equal ease.Some models may include additional features and accessories (such as automatic knife changer).Accelerate the production process.

2. High productivity and scalability: Once the design specifications and parameters have been set on the machine, it starts to perform tasks consistently and pays the price for flexible scalability.

3. Low maintenance: Due to the automation of digital machines, they update themselves automatically from time to time, thus simplifying the work process.They don't require regular service.The only thing you need to change from time to time is the cutting tool.Regular light cleaning will only improve the quality of work.None of this requires a call to a professional, which in turn minimizes overhead.

4. Minimum labor requirements: Several operators are required to perform production operations.The whole task can be accomplished by professional programmers and skilled operators, while in manual machines, the operator of each machine and the supervisor of management operations are required.

5. 24-hour endurance: nc engraving machine can work continuously.It can be delivered 24 hours a day unless repairs or necessary repairs are required.

6. Safe environment guarantee: CNC engraving machine provides a safer material cutting environment.Operators engaged in maintaining the proper functioning of the machine do not have to disturb themselves with sharp tools and tools, as is the case with traditional cutting methods.You can finish the work from a distance.

The Benefits of Laser Engraving

When you use a laser engraving machine to inscribe your industrial materials, you’ll experience all the advantages of this tried-and-true process, including:

Legible and permanent marks: Industrial laser engraver machines produce permanent, high-contrast markings that are easy to read. That means any product branding or identification code is highly visible to consumers.

High-speed operations: Conventional engraving methods can be tedious and time-consuming. Industrial laser marking systems speed up the engraving process with high-efficiency operations, helping companies create products faster while cutting costs.

Minimal consumables: Laser engraving requires few consumables, making it affordable, eco-friendly and energy-efficient.

Material marking versatility: With laser identification systems, you can mark a variety of materials types, such as metal, rubber, plastic, silicone, paper and wood.

Marking precision and accuracy: In laser engraving, the laser cutter does not make direct contact with the material, minimizing the risk of accidental markings. The process is highly precise and accurate, generating repeatable, uniform results.

Durability and wear resistance: Laser engraving systems produce durable markings that are resistant to harsh external factors due to robust material depression.

In short, the laser engraver uses laser melting or burning method to engrave, and the CNC router uses digital technology to control the cutter or the laser head and the ultrasonic head for engraving. The laser engraving machine can be a CNC carving machine. The CNC engraving machine can also be equipped with a laser head for engraving. The two are intersecting, and they are in an intersecting relationship.