Views: 17 Author: Site Editor Publish Time: 2022-04-20 Origin: Site

The machine carbon fiber are designed to cut metal at high speeds and with great precision. The carbon fiber laser cutter offers users a high degree of flexibility by combining a variety of laser processes into one machine. Angle cutting, slotting, marking, notching, and hole marking are all combined in this machine, making it an ideal solution for a wide range of applications.

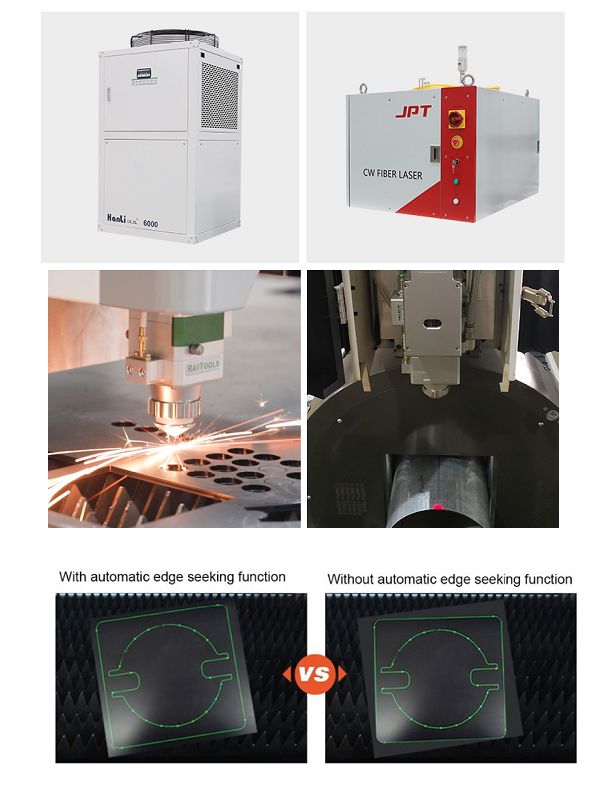

Laser fiber cutting outputs high-energy-density laser beam which is concentrated on the surface of the workpiece, therefore the area irradiated by the ultra-fine focus spot on the workpiece is instantly melted and vaporized, and the spot is moved by the CNC mechanical system to achieve automatic cutting by irradiating position, fast speed and high precision.

How to maximize the benefits of laser technology

One of the goals when designing for manufacturing is to achieve a simple solution, not a complex one. After all, complex designs are more difficult to manage, increase the potential for error, and create waste in the form of materials, energy, labor, and time. Laser cutting technology is a suitable tool for creating components of all shapes and sizes and is one of the most efficient and cost-effective manufacturing methods.

Complex cuts with good edge quality can be made precisely on laser cutting equipment. A precise laser beam creates close-tolerance components in a fast, clean and efficient manner with little operator intervention. Advanced software and narrow cuts allow parts to be tightly nested, maximizing yield and reducing material waste.

Keep it clean

The simplest thing you can do to prolong the life of your fiber laser cutting machine is to clean it. Operators must clean the device after every job. So please, empty all slag drawers and bins before attempting a new cut. If a worker doesn’t unpack a drawer after they use it, it’ll eventually jam shut. This can dramatically affect the table shuttle. Workers must clear off the slats before attempting another cut. Remove all scraps so that the new material lays flat on the surface and doesn’t tip upward.

Once you’re confident that the slat and drawers are clean, examine the torch. The torch is the nucleus of a fiber laser cutting machine. If this part malfunctions, there will be big trouble in the future. So, workers should clean the torch body, nozzle, attached cables, and the protective window. Operators can use lint-free cloths or microfiber towels to clean these parts. Cleaning the torch helps the laser make the most precise cuts possible.

It’s crucial to clean the area around the equipment as well. Any debris or scraps that surround the machine are a safety hazard. Workers can trip over these items and severely injure themselves. So, clean up and do a thorough inspection of the area before you turn it on. Also, check over the connections and watch out for loose wires that may cause you to trip. Cleaning is a simple task that can prevent massive headaches in the future.