Views: 7 Author: Site Editor Publish Time: 2022-05-17 Origin: Site

The advantage of this CNC wood carving and Engraving machine is that it is suitable for the processing of diversified and complex products or diversified processing, and has a wide range of uses.

1, after the engraving position, must put the X, Y, Z axis work-piece coordinate all classified as '0'.

2, adjusted the engraving speed and spindle motor speed, when the carving in case appear too fast, speed too slow and cutting knife.

3, automatic knife, pay attention to the knife block must be with engraving machine aluminum insulation mesa.

4, sculpture, not sure if the first knife or be afraid to make mistakes, can put the feed speed is slow, think carving normal speed back to normal again; It can also be simulated in idle sculpture, look to whether normal.

5, if not for a long time to use cheap wood carving machine, should be regularly go idle every week, it is best to every week, to ensure the flexibility of the transmission system.

6, for woodworking engraving machine running for ten hours/day in a row the following; Guarantee the normal work of the cooling water clean and the water pump, must not water shortage phenomenon in a water-cooled spindle motor, regular replacement of cooling water, in order to prevent the water temperature is too high, circulating water as much as possible, can change the large capacity water tank.

7, after each use woodworking engraving machine, should pay attention to clean up, will have to clean up the dust on the platform and drive system; Regularly for the transmission system of X, Y and Z axis lubrication oil.

8, operating personnel in the best operating woodworking engraving machine to wear dust masks and goggles, such as in the process to avoid the dust produced in human body, causing discomfort.

9, woodworking engraving machine carved daily maintenance methods in woodworking machine and dust dust removal device, dust removal equipment supporting the use.

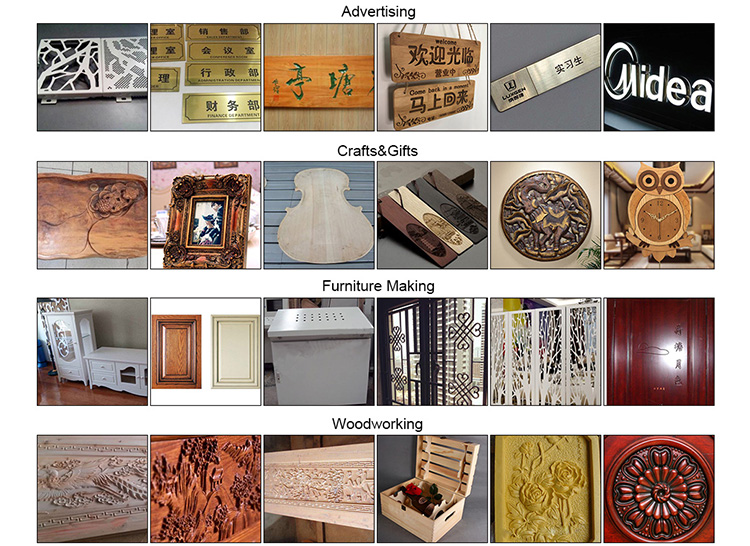

Scope of application

Four major characteristics of cnc woodworking router machine

Wood carving engraving machine is to designed to engrave and cut all kinds of metal and nonmetal materials,with the combined advantages of manual carving and traditional cnc machining at the same time.In this article,we will illustrate five characteristics of wood engraving cnc router.Hope this article will make you have a brand-new understanding of carving wood cnc router machine.

high precision

Industrial cnc wood engraving machine has high processing precision,product consistency is good.Under this circumstances,cnc carving router wood machine is suitable for mass production with precise size requirements.

2.low labor intensity,high degree of automation,less dependence on operators.

As the brain of cnc wood cutting and engraving machine,control system can automatically control the tool movement of cnc wood cutting router machine according to the processing instruction,completes the engraving task with high speed and high precision,greatly reduces the labor cost.The creation of cnc wood carving machine for sale is regarded as a big progress in woodworking industry,art and crafts industry,soft metal processing industry and advertising industry etc.

3.fine processing

Wood cutting and carving machineis mainly used for some fine processing industry,so normally China cnc router wood machine makes use of less than 6.0mm small router tools for processing.Furthermore,router tools are regarded as the great consumables for China cnc wood carving machine especially for industrial cnc stone carving machines.

4.high speed

CNC engraving wood machine for sale can also realize high-speed milling for aluminum,copper,steel etc.Wood engraving cutting machine is widely applied in seal making,company logo engraving and etc.

The CNC engraving machine is composed of three parts: computer, machine controller and machine. It is designed and typeset by special engraving software configured in the computer, the design and typesetting information is automatically transmitted to the machine controller by the computer, then the controller converts the information into a signal with power (pulse train) which can drive stepping motor or a servo motor, so it controls the engraving machine to generate the engraving path of the three axis of X, Y and Z. At the same time, the high-speed turning spindle on the engraving machine can engrave various plane or three-dimensional relief patterns and characters designed in the computer by cutting the machining materials fixed on the main table by the tools selected according to the processing material, to achieve automatic engraving work.