Views: 79 Author: igoldenCNC Publish Time: 2023-12-13 Origin: igoldencnc

Fiber laser metal cutting technology has revolutionized the way industries approach precision cutting. In an era where efficiency and accuracy are paramount, IGOLDENCNC stands at the forefront with state-of-the-art fiber laser metal cutting machines.

A fiber laser cutting machine is a type of laser cutting equipment specifically designed for precision cutting of various materials. It utilizes the power of a fiber laser to generate a concentrated and high-energy laser beam that can cut through different types of materials with high accuracy and speed.

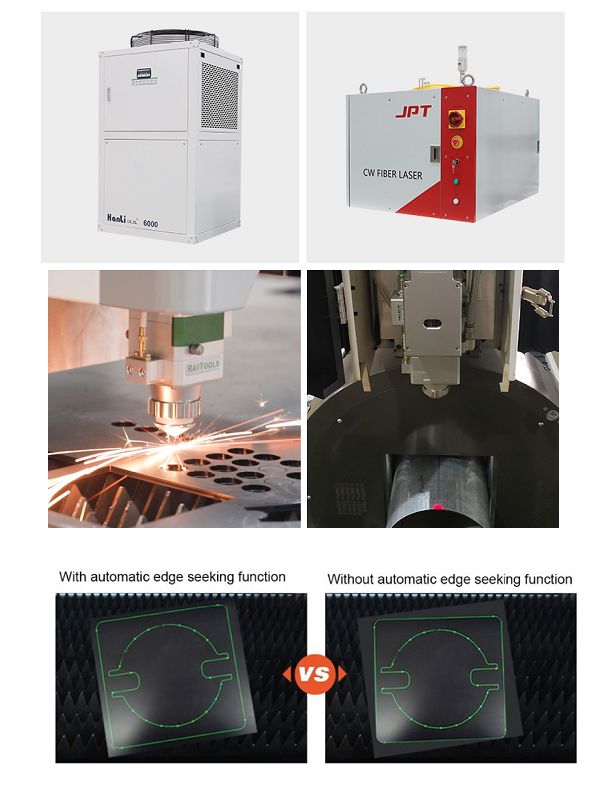

A typical fiber laser cutter comprises key components, such as a laser source, a cutting head, a numerical control system, a cutting bed, and a power supply. The laser source is essentially the heart of the machine. The cutting head has lenses that focus the laser beam onto the material for cutting. The cutting bed holds the material in place, and the numerical control system directs the laser source and cutting head based on the software's instructions.

You can choose different machines with different powers to fit materials with different thickness, you can also choose different machines with different size to fit materials with different size. It is equipped with laser power from 1000 Watts to 15000 Watts to cut metal materials. Fiber laser cutter is mainly divided into mini series, hobby series, small series, portable series, large format series according to sizes. Fiber laser cutter is mainly divided into sheet metal laser cutter types, laser tube cutter types according to applications.

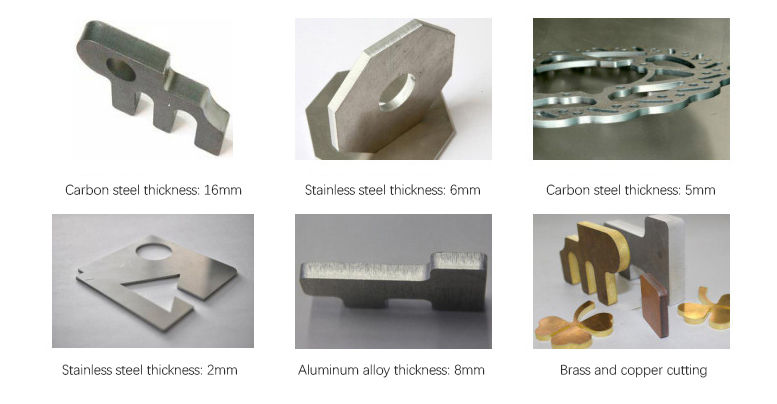

There is no doubt that iGOLDEN CNC Machinery can provide you with both fiber laser and CO2 laser to cut or engrave metal materials. The fiber laser beam can cut most of the metals, such as stainless steel, carbon steel, aluminum, brass, copper, steel, titanium, zinc, alloys, etc. And the laser cutting thickness can reach 50mm. While the CO2 laser beam can only cut and engrave very limited thin metal sheets, such as 2mm stainless steel sheets and 1mm carbon steel panels.

Some customers need to cut both metal sheet and tube, dual-use laser cutting machine that integrates the two functions is an ideal choice. The sheet and tube integrated laser cutting machine is equipped with advanced optical fiber laser sheet cutting system and tube cutting system. Different applications of sheet and tube cutting can be switched at will and the operation is so convenient that it can easily realize one machine dual-use and create more value for customers.

The dual function fiber laser cutting machine enables the cutting of metal sheets and tubes on the same machine. Ultra-large format, capable of cutting sheet width not exceeding 2000mm×6000mm, cutting pipe length 6m, pipe diameter 20mm~300mm.

New metal sheet and tuber laser cutting machine is an ideal entry-level laser cutting machine without any high purchase cost or training cost. It has easy operation and simple maintenance. One machine integrates two functions, reducing the floor space and improving efficiency.

It has more advantages than the traditional metal cutting equipment in cutting sheet and tube. No matter for sheets of different materials and tubes of different shapes, it can carry out efficient and accurate cutting. Laser tube and sheet integrated cutting machine quickly occupied the metal processing industry with its professional, stable cutting effect.

Tube fiber laser cutting machine is specially designed for pipes, easy to operate. This fiber laser cutting machine improves cutting quality and cutting efficiency. The fiber laser cutter is widely used in sports equipment, various types of pipe, water pipes, oil pipelines and other industries.Our tube laser cutter is the ultimate way to cut your metal tubes with ease. We can cut all kinds of square or round tubes and it is super quick, reliable and efficient. It uses less energy when cutting – using nitrogen, oxygen or air for the process. It is suitable for cutting through thick metals such as mild steel and even allows you to cut complex shapes with precision detail that no other method can do.

The Tube laser Cutting machine is designed to cut and engrave on square, rectangle, hexagonal or round tubes up to 220mm diameter and up to 6000mm long. It can be used for various tube-based applications such as graphic art, model building, games design and specific needs of industry.

Fast and easy to use, the Easy End Cuts can produce complex geometry on the tube ends, including a cope, fish mouth, and tab and slot. Using the laser on tubes is much faster, cleaner, and cheaper than using traditional hand or power tools. The fit-up between tubes comes out perfect every time.

both the collimating lens and the focusing lens group are cooling accessories. Besides, the cooling airflow nozzle is added, which effectively protects the nozzle and the ceramics and prolongs the working time.

through the 35 mm aperture, the interference of stray light is effectively reduced.

without human interference, the focusing speed can reach 10m/min, and the repeatability is about 50 microns.

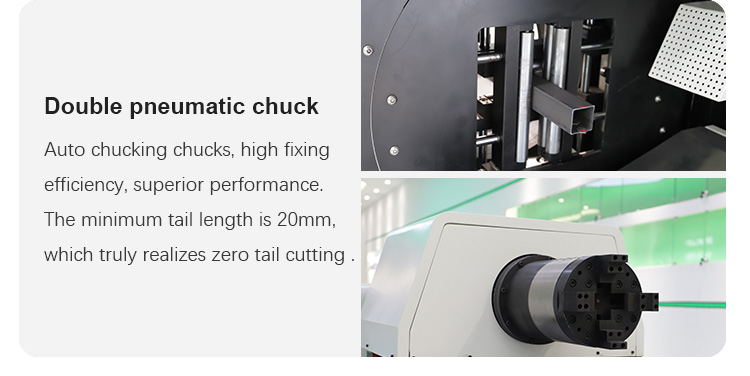

1) One-click chuck opening and automatic centering will reduce the waiting time for loading and unloading.

2) Pneumatic open clamp: with large and constant clamping force, the heavy pipe is not loose or slipped, which guarantees the cutting accuracy.

3) The special support frame can avoid the sagging deformation of the pipe, improve the cutting accuracy, and prolong the service life of the chuck.

Sheet metal CNC laser cutting is a technology that has revolutionized precision engineering. We offers cutting-edge solutions tailored for various applications and industries. This article explores the world of IGOLDENLASER's sheet metal CNC laser cutting machines.

Another great benefit of choosing a fiber laser cutting machine is its high efficiency. In many areas of the cutting process, laser cutters are the most efficient on the modern market - higher photoelectric conversion efficiency, more efficient beam delivery, resulting in better finished products and less energy waste.

The cutting accuracy is unmatched by other processes. When the power is stable and the parameters are suitable, there is no need for secondary processing and grinding, and the finished product can be directly finished, which is very cost-effective.

There is a misconception that the capabilities and applications of fiber laser cutting machines are limited to heavy-duty manufacturing, however this is not the case. There are many industries and industries that can use laser cutting machines, ranging from heavy equipment, rail transit, aerospace, small to jewelry processing, advertising board processing, and the power range is large, ranging from 1000W to 30000W, the thickest Can cut 130mm sheet.

Steel Laser Cutting Machine

A steel laser cutting machine is a specific type of laser cutting equipment designed specifically for cutting steel and other ferrous metals. It utilizes laser technology to produce highly precise cuts in steel sheets, plates, and other forms of steel materials.

Sheet metal laser cutter is a type of automatic metal plate cutting system that uses CO2 or fiber laser beam with CNC controller to cut stainless steel sheet, chromium steel sheet, martensitic steel sheet, ferritic steel plate, austenitic steel plate, carbon steel sheet, mild steel sheet, hot & cold rolled steel sheet, galvanized steel sheet, pre-plated steel sheet, aluminum plate, zinc plate, copper & brass sheet, as well as titanium, gold, and silver. Laser sheet metal cutters can deal with multi-variety, small-batch, customized, high-quality, short-delivery orders. It features with high precision, high speed, and high flexibility, which makes it to cut projects with special or complex shapes, and step-by-step replace the traditional sheet metal cutting tools, including plasma cutters, flame cutters, water jet cutters, CNC punching machines, CNC shearing machines, tin snips, and wire cutters. The sheet metal cutting tables (2x3, 2x4, 4x4, 4x8, 5x10, 6x12), laser generators (IPG, JPT, Raycus, MAX, RECI), and laser powers (300W - 40,000W) can be customized as your sheet metal cutting plans.

Ultimate Precision: IGOLDENLASER's laser fiber cutting machines offer an unprecedented level of accuracy, ensuring flawless execution of even the most intricate designs.

Speed and Efficiency: Our machines provide optimal cutting speeds without compromising quality, boosting productivity and efficiency.

Versatility Across Materials: From metals to plastics, IGOLDEN's laser fiber cutting technology can handle a wide range of materials.

Different Types of IGOLDENLaser Fiber Cutting MachinesIGOLDEN's array of solutions ensures that there’s a machine for every need.

Gantry rack double drive system, reinforced welding body. The stress is eliminated by tempering and vibration aging to ensure that the machine deformation tolerance is within 0.02 mm;

Crossbeam are made through drawing and finishing process: Lightweight, high rigidity, high dynamic performance;

Cutting head has the leapfrog function, parabolic motion between the cutting contours. Automatic frog jump during switching contours, high cutting efficiency;

Automatic concentrated lubrication function, automatic lubrication for traditional parts by system control.

No manual intervention is needed so as to ensure the accuracy and service life of the moving part.

Metal Fabrication: In the metal fabrication industry, fiber laser cutting machines are used to make precise cuts on metals such as steel, aluminum, copper, and brass. Whether it's for creating complex shapes or simple cutouts, the precision of these machines is invaluable.

Automotive Industry: In the automotive sector, fiber laser cutting machines are widely used for manufacturing various components. They are used in the production of parts ranging from simple brackets to intricate engine components. The ability to work with different types of metals makes these machines versatile for automotive production.

Aerospace Industry: The aerospace industry requires extremely precise components, and fiber laser cutting machines are perfectly suited to meet these requirements. They are used in the manufacture of aircraft and spacecraft components, where precision and consistency are of paramount importance.

Heavy Machinery Manufacturing: In the production of heavy machinery and equipment, fiber laser cutting machines play a vital role. They are used for cutting large, heavy pieces of metal used in the construction of machinery for sectors such as agriculture, mining, and construction.

Shipbuilding Industry: Shipbuilding involves working with large metal plates and structures. The fiber laser cutting machines are used for cutting and shaping these large metal components efficiently and accurately.

Kitchenware industry:Kitchenware is one of the essential metal products in our daily life. The traditional processing methods in the kitchenware manufacturing industry are facing difficulties such as low work efficiency, large consumption of molds, and high cost of use. Laser cutters have fast cutting speed and high precision, which improves processing efficiency, and can realize customization and personalized product development, solve the problems of kitchen utensil manufacturers, and have won the recognition of kitchen utensil manufacturers.

Sheet metal processing industry:With the rapid development of sheet metal processing technology, traditional sheet metal cutting equipment can no longer meet the current process and cutting shape requirements. Laser cutting has gradually replaced traditional equipment with its advantages of high flexibility and fast cutting speed. Fiber laser cutting machines' wide application in sheet metal processing is an inevitable trend.

This material will have better results when cut with oxygen. When oxygen is used as the processing gas, the cutting edge will oxidize slightly. For plates up to 4mm thick, nitrogen can be used as the processing gas for high-pressure cutting. In this case, the cutting edge will not be oxidized. For plates with a thickness of more than 10mm, better results can be obtained by using a special plate for the laser and oiling the surface of the workpiece during processing.

2. Stainless steel

Oxygen can be used where oxidation of the cutting end is acceptable; nitrogen is used to obtain an oxidation-free and burr-free edge, and no further treatment is required. Coating oil film on the surface of the plate will get a better perforation effect without reducing the processing quality.

3. Aluminum

With high reflectivity and thermal conductivity, aluminum materials up to 6mm thick can be cut, depending on the alloy type and laser capability. When cutting with oxygen, the cutting surface is rough and hard. When nitrogen is used, the cut surface is smooth. Pure aluminum is very difficult to cut because of its high purity, and it can only be cut when a "reflective absorption" device is installed on the system. Otherwise, reflections could destroy the optical components.

4. Titanium

Titanium plates are cut with argon and nitrogen,which act as processing gases. Other parameters can refer to nickel-chromium steel.

5. Copper and brass

Both materials have high reflectivity and very good thermal conductivity. Brass with a thickness of less than 1mm can be cut with nitrogen, copper with a thickness of less than 2mm can be cut, and the processing gas must be oxygen. Copper and brass can only be cut if the system is equipped with a protective device. Otherwise, reflections could destroy the laser source.

If you need to process any materials, please contact us, IGOLDEN will provide you with high-quality laser cutters.

First, the CO2 laser metal cutting machine price ranges from $2,000 to $20,000. While the fiber laser metal cutter price ranges from $20,000 to $200,000.

There are a lot of factors that can affect the metal laser cutting machine price, such as types, kits, brands, manufacturers, power, size, functions, etc. Therefore, the metal laser cutter cost will show a great difference.