Views: 13 Author: Site Editor Publish Time: 2021-12-14 Origin: Site

CNC Router Wood Engraving Machine or sale, best choice for automatic Wood 3D Carving, Cutting, Engraving; Portable rotary device on the table, meets the needs of column/pillar carving and take no space; Auto tool changer system manage tool bits shifting, all things are done automatically.

1.Parameter setting problem, when the CNC Router Wood Engraving Machine is positioned on the Z axis, do not let the knife touch the surface of the material, but move the material away, let the knife directly touch the table surface, and just touch it. There will be no depth here, but it will be returned first. Zero, and then according to the set cutting depth, zero the Z axis at this position, which is the origin of the Z axis.

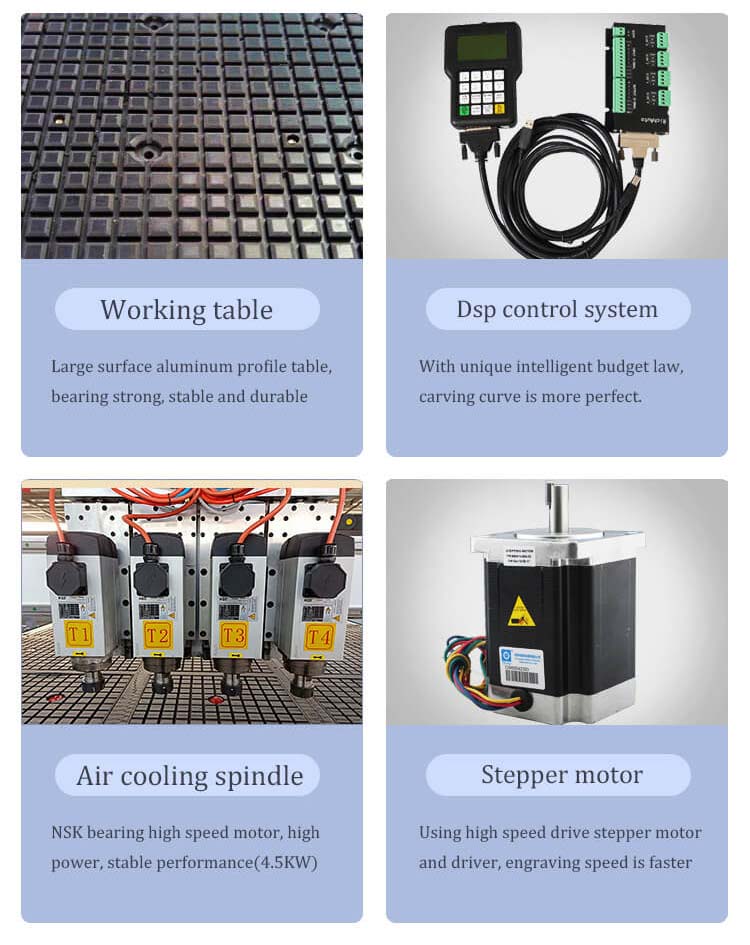

2.According to the depth set by the system, the CNC woodworking engraving machine returns to the zero position when it reaches the lowest point, just on the table, to ensure that the material is completely engraved without damaging the table of the CNC woodworking engraving machine. Second, add a protective board to the table of the router wood cnc, such as the thin Aosong board on the vacuum suction table. The Aosong board itself is loose and breathable, which will not affect the vacuum suction capacity and effectively avoid the inaccurate origin setting. The resulting tool damage and tabletop problems.

3.Even if the countertop of the woodworking cnc router machineis used with the above treatments, it will inevitably cause accidental scratches in long-term use. At this time, the countertop should be re-milled.When the bakelite or PVC on the countertop is too thin, a layer can be resurfaced . It should also be noted that when the machine leaves the factory, in order to prevent damage to the countertop during logistics and transportation, after-sales personnel are generally required to re-mill the countertop during installation and commissioning.

1. The main body of woodworking engraving machine is made of stainless steel alloy. The bed is quenched at high temperature, which provides a more stable processing platform for the machine tool, and the mechanical stress of the bed components has been removed before the bed is processed.

2. The positioning bearing, ball screw, linear guide and rack of the woodworking engraving machine are all supported by the centralized active smoothing system of the machine tool master control system.

3. The important parts of wood engraving machine models are top brands at home and abroad, such as the Japanese Yaskawa AC servo drive system, the Italian HSD electric spindle and the German export vacuum pump.

4. The vacuum adsorption table of the woodworking engraving machine is divided into six processing areas, which can be processed in one area or at the same time, which improves the processing efficiency

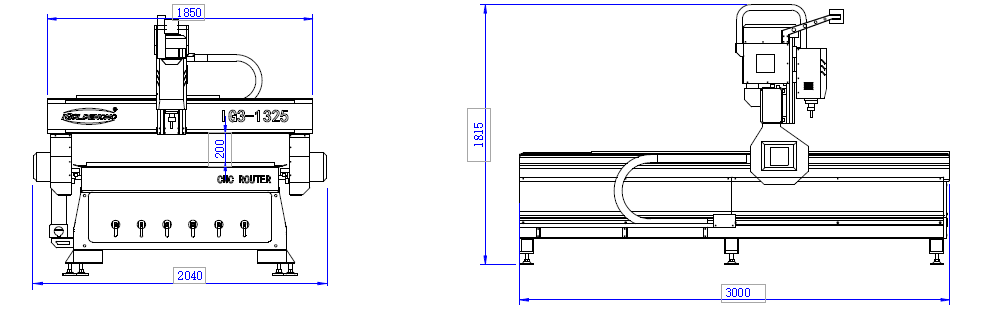

Model:1235(1300*2500)

Support customization