Views: 7 Author: Site Editor Publish Time: 2022-05-24 Origin: Site

What is Laser Cutting?

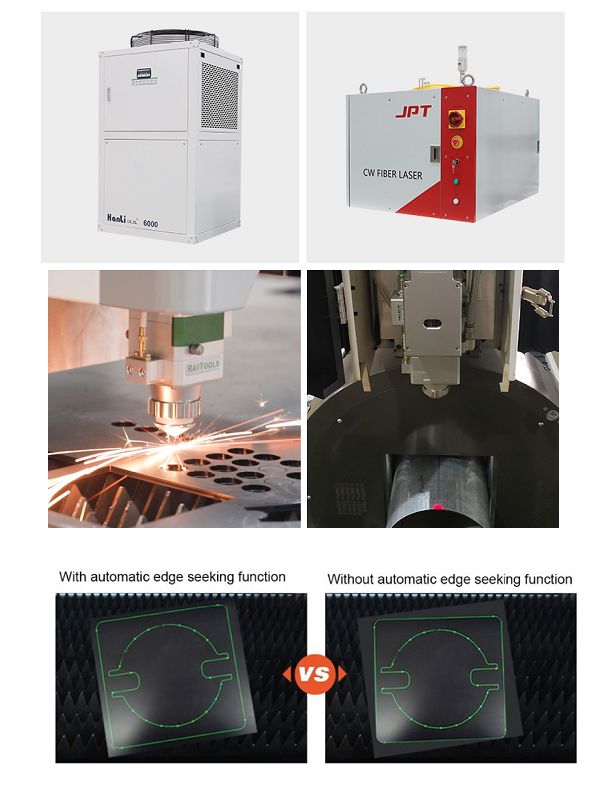

In the simplest terms, a CNC laser cutter uses a coherent beam of light to cut material, most often sheet metal, but also wood, diamond, glass, plastics and silicon.image-center

In the beginning, the beam was directed through a lens via mirrors, but these days fiber optics are much more common. The lens focuses the beam at the work zone to burn, melt or vaporize the material. Exactly which process(es) the material undergoes depends on the type of laser cutting involved.

laser iron cutting machine is used in everything from manufacturing to surgery. With its many applications, laser cutting is crucial to the success of many companies. If you're interested in using laser cutting for your business, you should know how the laser cutting process works and how a laser cutter functions. You should also know the primary types of laser cutters and their main applications. This article will give you all the details you need.

Laser iron cutting machine is a digital manufacturing technology, working on 2D vector files. The laser cutter itself is built of a laser resonator which, depending on the cutting method, contains either a gas mixture of a crystal body or glass fibers. The cutting process starts when energy is applied to the mixture, which is then sent through different mirror lenses focusing the laser.

Thanks to the series of mirrors, the laser beam is sent through nozzle straight at the material. When it makes contact with the surface, it vaporizes the material in the shape of the vector file. Part of the material which is melted with the laser is called kerf and needs to be considered in your design. You can find all the information about it on each page of our materials.

Five precautions for using fiber laser cutting machine

1) The dual-focus laser cutting head is a fragile item on the laser cutting machine. Long-term use will cause damage to the laser cutting head.

2) Use a vacuum cleaner to suck up the dust and dirt in the machine once a week. All electrical cabinets should be closed to prevent dust.

3) Check the straightness of the fiber laser cutting machine track and the verticality of the machine every six months, and find that it is abnormal and maintain and debug in time. If this is not done, the cutting effect may not be very good, the error will increase, and the cutting will be affected. Qualitatively. This is the top priority and must be done.

4) The guide rails of the fiber laser cutting machine should be cleaned frequently to remove dust and other debris to ensure that the equipment is normal. The rack should be wiped frequently and lubricated to ensure lubrication without debris. The guide rail should be cleaned and lubricated frequently, and the motor should also be cleaned and lubricated frequently. The machine can move better and cut more accurately when the machine is moving. The quality of the cut product will be better. improve.

5) Check the steel belt of the fiber laser cutting machine frequently to ensure that it is tight. Otherwise, if there is a problem in operation, it may hurt people, or even cause death in serious cases. The steel belt looks like a small thing, but the problem is still a bit serious.