Views: 7 Author: igoldenCNC Publish Time: 2023-05-20 Origin: igoldencnc

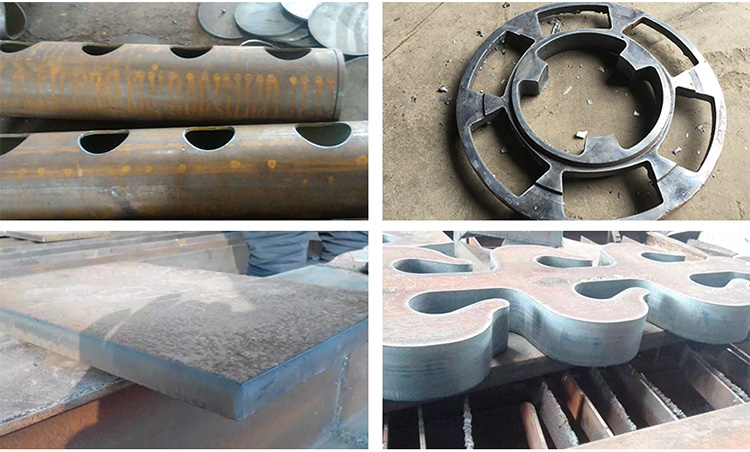

A plasma cutting table CNC is a computer-controlled machine that uses plasma technology to cut metal materials with a high level of precision and efficiency. This machine is specifically designed for metalworking industries that require accurate and efficient cutting of various metal materials, such as steel, aluminum, and copper.

One of the main benefits of using a plasma cutting table CNC is its high precision and accuracy. The machine can make cuts with a high level of consistency, which is important for manufacturers who require precise measurements for their products. Additionally, the machine can cut complex shapes and designs, which would be challenging or impossible to achieve using traditional cutting methods.

Another benefit of using a plasma cutting table CNC is its efficiency. The machine can perform various cutting tasks, including drilling, slotting, and beveling, in a single process. This reduces the time required for production and increases the overall efficiency of the manufacturing process.

Overall, a plasma cutting table CNC is a valuable investment for any metalworking industry that requires precise and efficient cutting of various metal materials. It offers high accuracy, versatility, and efficiency, making it an essential tool for producing high-quality products. Additionally, the CNC technology used in the machine allows for easy and precise customization of cutting designs, making it a versatile tool for a wide range of metalworking applications.

Plasma Cutting Technology: Plasma cutting utilizes a high-temperature plasma arc to melt through metals, allowing for precise and efficient cutting. The plasma torch, controlled by the CNC system, moves along the cutting table to create desired shapes and cuts.

Cutting Table Size: Plasma cutting tables come in various sizes, and it's important to choose one that suits your cutting needs. Consider the dimensions of the table, including its length, width, and cutting area, to ensure it can accommodate the material sizes you'll be working with.

CNC Control System: The CNC system controls the movement of the plasma torch along the cutting table, following the programmed instructions. Look for a cutting table with a reliable and user-friendly CNC control system that offers advanced features like nesting, automatic tool path generation, and compatibility with common file formats.

Cutting Capacity: Different plasma cutting tables have varying cutting capacities in terms of thickness and types of materials they can handle. Consider the maximum material thickness and types of metals (such as steel, stainless steel, aluminum) that the machine can effectively cut.

Precision and Speed: The precision and cutting speed of a plasma cutting table are crucial factors. Look for a machine that offers high cutting accuracy and speed, allowing for efficient production and minimal post-cutting cleanup.

Software Compatibility: Ensure that the cutting table's control software is compatible with your computer system and supports the file formats commonly used for plasma cutting, such as DXF, DWG, and AI. This allows you to import and convert your design files seamlessly.

Safety Features: Plasma cutting involves high temperatures and potential hazards. Look for safety features like fume extraction systems, safety interlocks, and protective enclosures to ensure a safe working environment.

Support and Service: Consider the availability of technical support, training, and after-sales service provided by the manufacturer or distributor. Reliable support is essential for troubleshooting issues and maximizing machine uptime.

Cost and Budget: Plasma cutting tables can vary significantly in price depending on their size, cutting capacity, features, and brand. Set a budget and find a machine that offers the necessary functionality within your financial constraints.

It's crucial to thoroughly research and evaluate different plasma cutting table CNC options based on your specific cutting requirements, material types, thicknesses, and desired features to select the most suitable machine for your needs.