Views: 165 Author: igoldenCNC Publish Time: 2024-12-13 Origin: igoldenCNC

In today's fast-paced world, industries are constantly evolving, seeking the most efficient and environmentally-friendly ways to improve their processes. One such innovation is the laser rust removal machine, a breakthrough technology that is transforming the way rust and other contaminants are removed from metal surfaces. Whether you're dealing with industrial machinery, automotive parts, or metal artwork, the ability to efficiently and precisely remove rust without damaging the underlying material is crucial.

Laser rust removal Machines can also be called laser cleaning machines, is a cutting-edge device that uses laser technology to remove rust, dirt, paint, and other contaminants from metal surfaces. Unlike traditional abrasive methods, laser rust removal uses high-intensity laser beams to vaporize rust or contaminants. The result is a clean, rust-free surface without the risk of scratching, warping, or damaging the material beneath.The laser-cleaning machine comes with an air or water cooling system. It is necessary to prevent a laser source and a scanner (if it is a water-cooled type) from overheating during operation.

Laser rust removal machines are equipped with advanced laser systems that can be finely controlled to target specific areas. They are highly efficient, precise, and require minimal maintenance. This method of rust removal is increasingly popular in industries where precision is paramount, such as aerospace, automotive, manufacturing, and metal restoration.

Laser rust removal works by focusing a high-powered laser beam on the rusted or contaminated surface. The laser energy is absorbed by the rust or unwanted material, causing it to heat up rapidly and vaporize. This process leaves the underlying metal intact while effectively removing the rust or contaminants.

Here’s how it works in detail:

Laser Emission

The laser system emits a focused, high-energy beam that is directed at the surface of the material.

Absorption by Rust

The rust absorbs the laser energy more efficiently than the underlying metal. This is due to the fact that rust (iron oxide) has a different absorption rate compared to clean metal.

Vaporization

As the laser heats the rust, it begins to vaporize and is removed from the surface. The vaporized rust is typically blown away by a stream of air or vacuum to prevent it from re-settling.

Surface Protection

Since the laser energy is highly focused, it only affects the rust and not the underlying material, preserving the integrity of the metal surface. This makes laser rust removal ideal for delicate materials and intricate parts.

Efficient Process

The laser system can be moved along the surface using robotic arms or handheld tools, allowing for efficient cleaning of large or hard-to-reach areas.

The introduction of laser rust removal machines has brought numerous advantages to industries that previously relied on traditional rust removal methods like sandblasting, chemical cleaning, or mechanical abrasion. Here are some key benefits:

Laser rust removal is incredibly precise. The focused laser beam can be adjusted to remove rust from specific areas, ensuring that no damage is done to the surrounding surface. This makes laser cleaning ideal for delicate components or intricate metal parts that require a high degree of accuracy.

Unlike traditional rust removal methods that may involve harsh chemicals or abrasive materials, laser rust removal is environmentally friendly. It does not produce chemical waste, and there is no need for harsh abrasives or solvents, making it a safer option for both operators and the environment.

Traditional methods like sandblasting or mechanical grinding can cause surface damage, such as scratches or grooves. Laser rust removal, on the other hand, only affects the rust or contaminants, preserving the integrity of the underlying material. This is particularly important when working with sensitive or expensive materials like stainless steel, aluminum, or delicate components.

Many traditional rust removal methods require consumables such as abrasive materials, chemicals, or solvents. These consumables must be regularly replaced, increasing ongoing operational costs. With a laser rust removal machine, there are no consumables required, making it a more cost-effective long-term solution.

Laser rust removal machines are much faster than traditional methods. The laser can cover large areas quickly and precisely, reducing downtime in industrial processes. Furthermore, the machine can be programmed to clean specific sections or hard-to-reach areas with minimal effort, enhancing overall efficiency.

Laser rust removal is a safer process compared to abrasive methods. There is no risk of inhaling harmful dust or chemicals, and the process generates minimal debris. However, operators must still follow appropriate safety measures, such as wearing protective eyewear, as lasers can pose a risk to the eyes.

The main advantage of laser cleaning is that it is non-contact. The nozzle does not touch the treated surface. Thus, the processed material is not damaged. The laser beam evaporates contaminants only. The main difference between laser and mechanical cleaning is non-contact treatment. Traditional cleaning methods can damage the product by sandblasting media or chemical solvents.

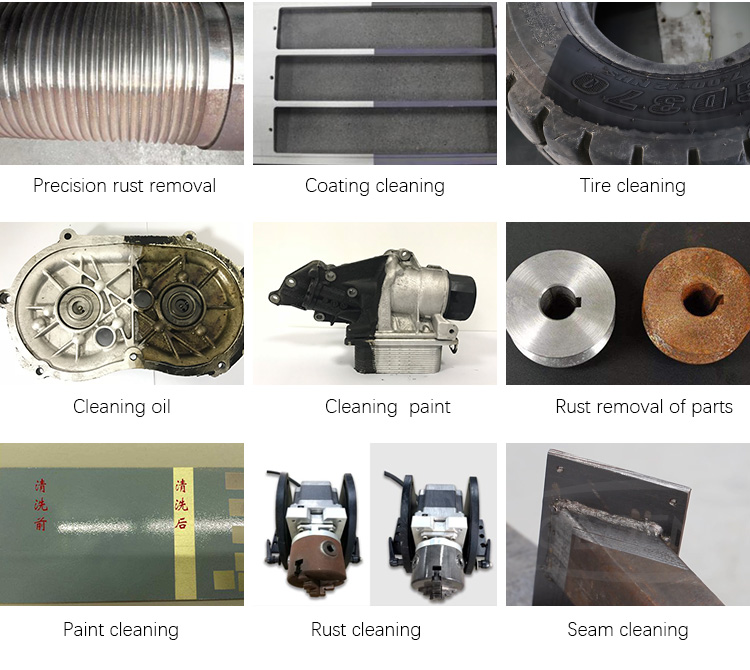

Laser rust removal technology has a wide range of applications across various industries, from manufacturing to restoration. Below are some of the key industries where this technology is making a significant impact:

In the automotive industry, laser rust removal is used to clean and restore metal parts, including car bodies, engines, and other components. The precision of laser cleaning ensures that parts are cleaned without damaging sensitive areas, such as paint or coatings. Additionally, it’s an excellent way to remove rust from car frames, wheels, and other metallic components, improving their longevity and appearance.

The aerospace industry requires high-quality, rust-free metal components for safety and performance reasons. Laser rust removal machines are ideal for cleaning turbine blades, aircraft bodies, and other metal parts, ensuring they are free of rust and contaminants without compromising their strength or integrity.

In manufacturing facilities, laser rust removal machines are used for cleaning heavy machinery and parts. Rust and dirt can accumulate on machine parts, leading to breakdowns and reduced efficiency. Laser cleaning can help restore the functionality of these machines, reducing maintenance costs and improving productivity.

Laser rust removal is also widely used in the restoration of old or antique metal objects, such as statues, monuments, and historical artifacts. The precision of laser cleaning allows conservators to remove rust without damaging the delicate surface, preserving the historical value of the items.

Rust removal is critical in the maritime industry, where ships and offshore structures are constantly exposed to harsh environments. Laser rust removal is used to clean and maintain metal surfaces on ships, oil rigs, and other marine structures. The method is highly effective in removing salt deposits, rust, and marine growth from steel and other metals.

Electronics and electrical components are often susceptible to corrosion and rust, which can affect performance. Laser rust removal is used to clean these components with precision, ensuring that they continue to function optimally and last longer.

When selecting a laser rust removal machine, several factors need to be considered to ensure that it meets your specific requirements:

The power of the laser will determine how quickly and effectively rust can be removed. High-powered lasers are ideal for large-scale industrial applications, while lower-powered lasers may be more suited for small-scale or delicate work.

Different laser types are used for rust removal, including fiber lasers, CO2 lasers, and diode lasers. Fiber lasers are the most commonly used in rust removal applications because of their efficiency and ability to generate high-intensity beams.

Some laser rust removal machines are designed for stationary use, while others are portable. Portable machines are ideal for fieldwork or when rust removal needs to be done on large or immovable objects.

The ease of use and flexibility of the machine’s software is an important consideration. Look for a machine with user-friendly software that allows for precise control of the laser and the ability to program different cleaning patterns.

While laser rust removal machines offer numerous benefits, they can be a significant investment. Consider the long-term savings in maintenance costs, consumables, and labor when calculating the return on investment.

The laser rust removal machine is a game-changer in industries that require precision, efficiency, and environmental responsibility. From automotive and aerospace to manufacturing and art restoration, these machines offer a superior alternative to traditional rust removal methods. Their precision, speed, and minimal environmental impact make them the ideal solution for a wide range of rust removal applications.

If you're looking for an efficient, eco-friendly, and cost-effective solution for removing rust, a laser rust removal machine is undoubtedly the way to go. By investing in this advanced technology, you can ensure that your metal surfaces are clean, smooth, and free of contaminants, thereby extending the life of your equipment and reducing maintenance costs.