iGCL-MOPA

iGOLDENCNC

iGCL-MOPA-Air

| Availability: | |

|---|---|

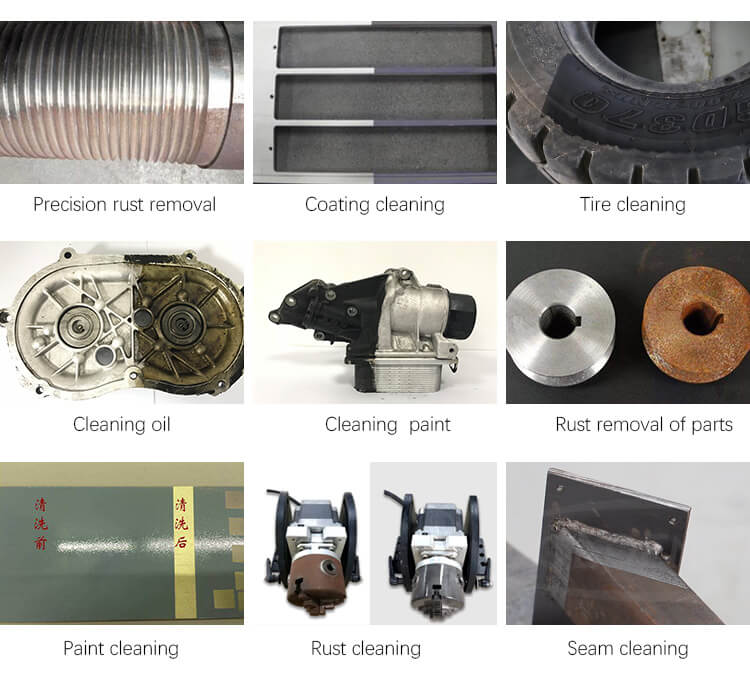

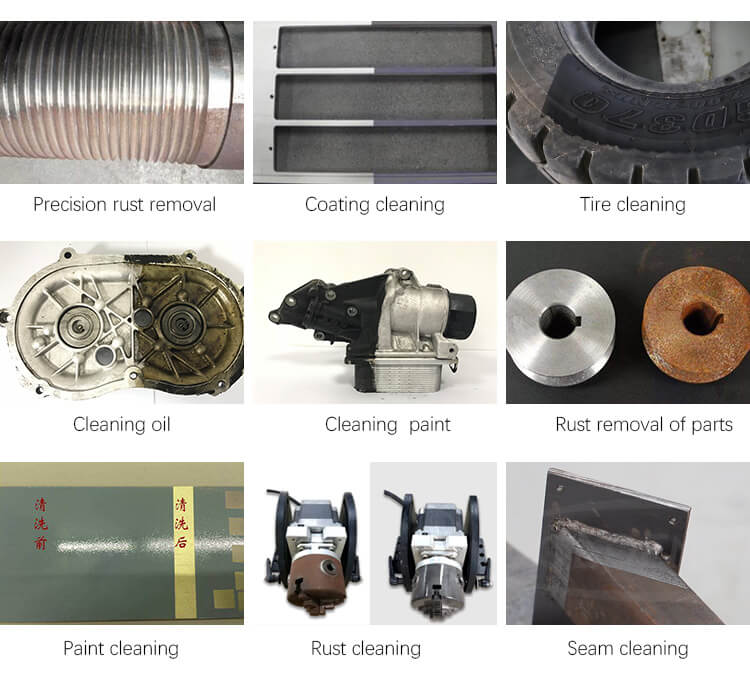

Pulse laser cleaning machines are advanced tools used for precision cleaning and surface preparation. They employ short bursts of high-intensity laser light to remove contaminants, oxides, paint, rust, and other unwanted materials from various surfaces without causing damage to the substrate.

The use of high frequency high energy laser pulse irradiate the workpiece surface, make the surface oil, rust or coating instantaneous evaporation or stripping, high-speed and effective cleaning object surface attachment or surface coating, so as to achieve a clean cleaning object process.

It is characterized by no damage to the parts matrix, no consumables, energy saving and environmental protection, to meet the requirements of complex modeling and fine positioning in the field of industrial processing, to achieve a higher cleaning effect and a lower overall cost of production benefits.

Laser cleaning machine is a new generation of high-tech products used for surface cleaning, can effectively remove the surface adhesion or surface coating of the cleaned object at high speed, so as to achieve a clean process.

Touch screen panel

Friendly interface; Rich functions, a variety of cleaning modes are optional, easy to learn.

Hand cleaning head

Small and light, different cleaning modes, multi-system compatible.

Fiber laser

Stable performance, low energy consumption, low failure rate, flexible optical fiber 5-20m, flexible and convenient, can achieve outdoor work, and has a rigid protective layer.

Portable and Lightweight: Pulse laser cleaning machines are designed to be compact and easy to move, allowing for flexibility in different cleaning scenarios.

Handheld Operation: The cleaning head of a pulse laser cleaning machine is lightweight and can be operated by hand for extended periods, making it suitable for various cleaning tasks.

High Cleaning Efficiency: Pulse laser cleaning machines offer improved cleaning efficiency compared to lower-powered models, allowing for faster and more effective cleaning.

Adjustable Parameters: These machines often come with adjustable parameters, such as laser power and beam size, to cater to different cleaning requirements.

Remote Control: Some pulse laser cleaning machines feature wireless control, enabling users to remotely set parameters and control the emission of laser beams.

Automotive Industry: Pulse laser cleaning machines can be used to remove rust, paint, and other contaminants from car bodies, engine parts, and other automotive components.

Manufacturing and Maintenance: These machines are suitable for cleaning machinery, equipment, molds, and other industrial components, ensuring optimal performance and longevity.

Aerospace Industry: Pulse laser cleaning machines can effectively clean aircraft parts, including engine components, turbine blades, and landing gear, without causing damage.

Electronics and Semiconductor Industry: These machines are used to clean delicate electronic components, circuit boards, and semiconductor wafers, ensuring optimal functionality.

Cultural Heritage Restoration: Pulse laser cleaning machines are employed in the restoration of cultural artifacts, such as statues, sculptures, and historical buildings, without causing damage to the original material.

We will provide a manual with simple troubleshooting of the machine, which will help you deal with common problems on the machine.

We will provide a lot of technical support and after-sale service online, just like detailed technical and installation instructions. For example, when you encounter a maintenance problem, we will make a complete and detailed video of the operation process based on the problem, it seems that I am on your side to guide you on how to deal with the problem.

3-Fast spare parts and technical assistance

Our large amount of spare parts inventory means that replacement parts will be delivered to you as soon as you are in demand. Get technical help right away by email or phone.

4-Free training services

We insist on hands-on training for customers on each machine sold. The training is free and we will cooperate with you to ensure that you operate comfortably with your new machine.

We feel proud of our expertise and educational ability for installing, properly maintaining and most effectively using iGOLDENCNC machines.

5-Special design, customized, OEM order

iGOLDENCNC is willing to help you realize your special ideas and requirements with our innovative ability. Therefore, when you need specially designed or customized machines and OEM machines, please contact us immediately.

Pulse laser cleaning machines are advanced tools used for precision cleaning and surface preparation. They employ short bursts of high-intensity laser light to remove contaminants, oxides, paint, rust, and other unwanted materials from various surfaces without causing damage to the substrate.

The use of high frequency high energy laser pulse irradiate the workpiece surface, make the surface oil, rust or coating instantaneous evaporation or stripping, high-speed and effective cleaning object surface attachment or surface coating, so as to achieve a clean cleaning object process.

It is characterized by no damage to the parts matrix, no consumables, energy saving and environmental protection, to meet the requirements of complex modeling and fine positioning in the field of industrial processing, to achieve a higher cleaning effect and a lower overall cost of production benefits.

Laser cleaning machine is a new generation of high-tech products used for surface cleaning, can effectively remove the surface adhesion or surface coating of the cleaned object at high speed, so as to achieve a clean process.

Touch screen panel

Friendly interface; Rich functions, a variety of cleaning modes are optional, easy to learn.

Hand cleaning head

Small and light, different cleaning modes, multi-system compatible.

Fiber laser

Stable performance, low energy consumption, low failure rate, flexible optical fiber 5-20m, flexible and convenient, can achieve outdoor work, and has a rigid protective layer.

Portable and Lightweight: Pulse laser cleaning machines are designed to be compact and easy to move, allowing for flexibility in different cleaning scenarios.

Handheld Operation: The cleaning head of a pulse laser cleaning machine is lightweight and can be operated by hand for extended periods, making it suitable for various cleaning tasks.

High Cleaning Efficiency: Pulse laser cleaning machines offer improved cleaning efficiency compared to lower-powered models, allowing for faster and more effective cleaning.

Adjustable Parameters: These machines often come with adjustable parameters, such as laser power and beam size, to cater to different cleaning requirements.

Remote Control: Some pulse laser cleaning machines feature wireless control, enabling users to remotely set parameters and control the emission of laser beams.

Automotive Industry: Pulse laser cleaning machines can be used to remove rust, paint, and other contaminants from car bodies, engine parts, and other automotive components.

Manufacturing and Maintenance: These machines are suitable for cleaning machinery, equipment, molds, and other industrial components, ensuring optimal performance and longevity.

Aerospace Industry: Pulse laser cleaning machines can effectively clean aircraft parts, including engine components, turbine blades, and landing gear, without causing damage.

Electronics and Semiconductor Industry: These machines are used to clean delicate electronic components, circuit boards, and semiconductor wafers, ensuring optimal functionality.

Cultural Heritage Restoration: Pulse laser cleaning machines are employed in the restoration of cultural artifacts, such as statues, sculptures, and historical buildings, without causing damage to the original material.

We will provide a manual with simple troubleshooting of the machine, which will help you deal with common problems on the machine.

We will provide a lot of technical support and after-sale service online, just like detailed technical and installation instructions. For example, when you encounter a maintenance problem, we will make a complete and detailed video of the operation process based on the problem, it seems that I am on your side to guide you on how to deal with the problem.

3-Fast spare parts and technical assistance

Our large amount of spare parts inventory means that replacement parts will be delivered to you as soon as you are in demand. Get technical help right away by email or phone.

4-Free training services

We insist on hands-on training for customers on each machine sold. The training is free and we will cooperate with you to ensure that you operate comfortably with your new machine.

We feel proud of our expertise and educational ability for installing, properly maintaining and most effectively using iGOLDENCNC machines.

5-Special design, customized, OEM order

iGOLDENCNC is willing to help you realize your special ideas and requirements with our innovative ability. Therefore, when you need specially designed or customized machines and OEM machines, please contact us immediately.