Views: 6 Author: Site Editor Publish Time: 2022-05-26 Origin: Site

Today we will explain to you some points to note when using flatbed plasma cutter outdoors:

As a material processing equipment, CNC plasma cutting machines are generally installed and used in the plant. The main reason is the maintenance of traditional components and control systems, due to the safety of electricity, gas, and other fuels involved in the flame cutting machine for sale. It is recommended that users also try to use indoors as much as possible. Secondly, the operation of the plasma system is very simple. The professional system is basically equipped with all the facilities required by the operator to start the operation, the power supply for cutting and gouging, the cutting torch and wearing parts, as well as the operating instructions in printed and DVD format. The operator only needs to prepare power, gas, and gloves, and goggles.

1. When it rains, try to keep the CNC system in good condition to prevent water ingress;

2. Always check the oxygen-acetylene pipeline;

3. Check whether there is leakage in the circuit;

4. Wipe the guide rail frequently to prevent rust.

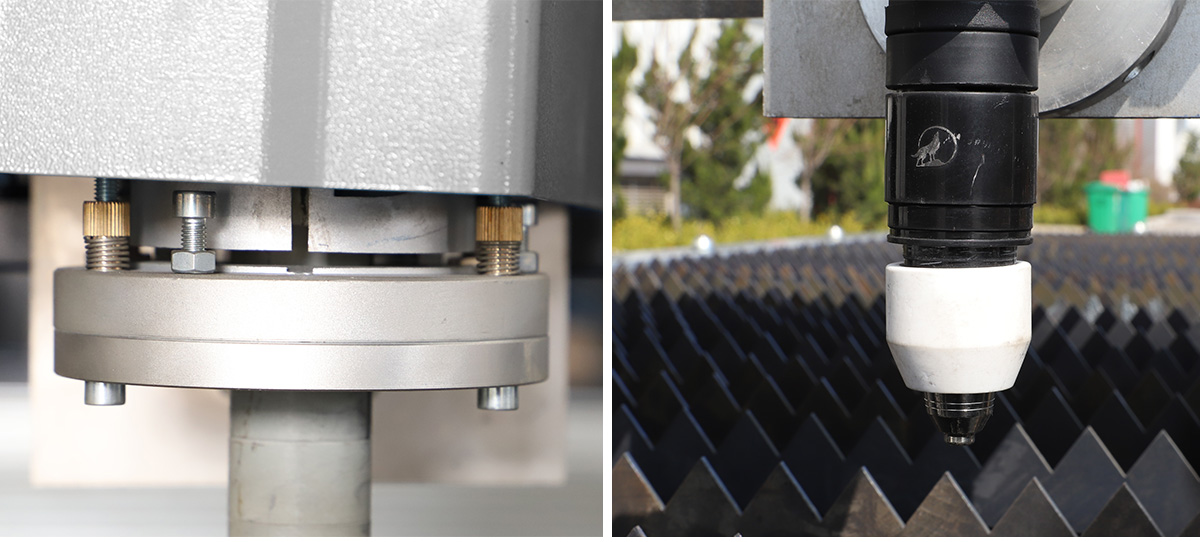

The fastcut cnc plasma table is one of the most fine-tuned, broadly used, efficient and versatile tools for cutting even heavyweight and thick materials quite quickly. When it comes to cutting materials for various types of manufacturing and construction applications, nothing gets the job done quite like a CNC plasma cutting table. Plasma cutting machines are computer automated, which allows for an incredibly high level accuracy for a precise cut every single time. They are successfully used in the metal cutting processes in the manufacturing, agricultural, engineering and construction industries. A CNC plasma table can change the way you cut metal, serving as the perfect addition for a small shop, a metal artist or a hobbyist and it can help save time, material and money.

Plasma cutting process:

Plasma arc cutting is capable of cutting all metals. The process is commonly used to cut steel, stainless steel and aluminum. Plasma cutting systems range in amperage output from 20 to 1,000 amps. High definition plasma systems using oxygen as the plasma gas have a capacity of piercing and production cutting steel up to 2.0” at 400 amps. High power systems using plasma gas mixtures of argon and hydrogen have the capacity to cut up to 6.0” stainless or aluminum at 1,000 amps.

Plasma Arc Cutting (PAC) power supplies are the Constant Current (CC) type as are powers supplies used for stick electrode (SMAW) and TIG welding (GTAW). However, PAC power supplies output much higher voltage. Open circuit voltage may be as high as 400 VDC. Constricting the plasma jet through a nozzle increases the arc density. Plasma cutting torches include a component to swirl the plasma gas forcing non-ionized gases outward. Swirling the plasma gas causes the cooler un-ionized boundary layer of gas around the plasma column to become wider, squeezing the arc and further increasing the arc density, length and temperature. Swirling the plasma gas also increases nozzle life. The plasma arc column can achieve temperatures of approx. 24,000º K (or 42,000º F).