Views: 45 Author: Site Editor Publish Time: 2022-01-19 Origin: Site

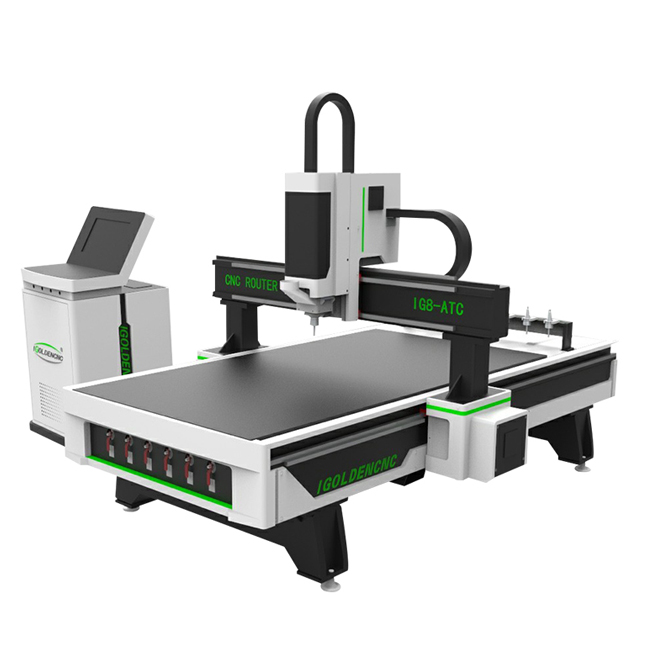

The CNC wood router is designed for carving and engraving wood, acrylic, PVC, double-colored, MDF, glass, and rubber boards. It is perfect for plane processing along the X, Y, and X axes. Both its worktable sizes and machine configurations can be customized according to users’ demands. It is widely used in cutting, carving, and engraving wood furniture, doors, cabinets, acrylic letters, signs, etc.

CNC wood routers based on the axis

CNC wood router machine has most commonly of 3 axes. But depending on the complexity of the design, the CNC wood router can further have three kinds. They are:

3-axis CNC routers

What’s 3 Axis CNC Router?

3 Axis CNC Milling evolved from the practice of rotary filing and is a milling process that operated on two axes, the X & Y-axis. In the three-axis machining, the workpiece remains still while the cutting tool moves along the 3 axes to mill the part. 3-axis machining still one of the most widely used techniques to create mechanical parts, and can be used for automatic/interactive operation, milling slots, drilling holes, and cutting sharp edges. Because 3-axis machining only operates on the 3 axes, it’s relatively simple and allows the material to be removed in these 3 axes represented by back to front, side to side and up and down. Three-axis CNC machining applications include Contoured shapes from flat stock, hole features, sculptured surfaces, tapered, or draft surfaces.

4-axis CNC routers:

What’s 4 axis CNC router?

4 axis CNC router is to increase the fourth axis C axis on the basis of the ordinary plane three axis CNC router machine. The existence of the C-axis can be a main shaft that swings from side to side and rotates 180°, or it can add an additional rotating shaft that can rotate 360°.

The main shaft can swing 180°C axis left and right. This 4 axis CNC machine can not only realize plane processing, but also realize double-sided processing. And mainly do some surface treatment of 3D workpieces.

Another type of 4 axis CNC router is also called rotary axis CNC router machine. Compared with the 3-axis CNC router machine, this type of 4-axis CNC machine adds a rotating device to the 3-axis CNC router. The rotary device mainly realizes the processing of cylindrical workpieces. It should be noted that whether it is the X-axis or Y-axis direction of the machine, the rotating device can be placed in any position you want. In addition, the rotating device can not only be placed on the machine, but also independent of the machine. And easier to operate, maintain and transport. Therefore, the CNC 4 axis router can realize the machining and planing engraving of cylindrical workpieces.

5-axis CNC routers:

What’s 5 axis CNC router?

5 axis CNC router is somewhat like the 3/4 axis CNC router, but 5 axis CNC router has two additional axis they can move along. These additional axis allow for shorter project time due to their capability of cutting five edges of the material simultaneously. They are designed for trimming formed parts, patterns or molds using five-axis simultaneous motions and smaller applications to larger aerospace and composite applications utilizing large/heavy fixtures. And widely used in large automotive molds, Styrofoam mold, cartoon character statue, garden three-dimensional sculpture, casting mold wood mold, lost mold, plastic mold, luggage mold, ceramic mold development and other high-precision three-dimensional products processing.

- Applications CNC wood routers are the most common CNC router machines for woodworking in industrial manufacturing, small business, small shop, home business, home shop, school education, craftsman, and hobbyists.

1. Furniture Making: home furnitures, art furnitures, antique furnitures, office furnitures, cabinet making, door making, cabinet doors, interior doors, home doors, cupboard doors, table legs, sofa legs, wood spindles, corners, screens, headboards, composite gates, MDF projects, wood crafts, wood arts.

2. Advertising.

3. Die Making.

4. Hollow Woodworks.

5. Relief Carvings.

6. Wood Cylinders.

7. 3D Woodworking Projects.

8. Sign Making.

9. Custom Woodworking Plans.

The useful maintenance for CNC wood router machine:

Notice of use:

For editing:

1, at the end of the engraving position, users of wood cnc engraver router must set X, Y, Z axis coordinates as "0".

2, set the engraving speed and spindle motor speed well, so as to prevent the knife broken from the fast engraving speed or low carving speed.

3, when automatic tool presetting, users of cnc wood engraver cutter router should know that the tool block must be insulated with the aluminum working table of cnc route for wood carving.

4, when carving, if operator is not confident of the precision of the first knife or afraid of making mistakes, he can slow down the feed speed and make the engraving speed normal when he thinks the engraving work is normal and good; operators can also simulate engraving path in the empty course to see whether it is normal or not.

5, if the cnc woodworking engraving router machine isn’t used for a long time, it should be regularly maintained every week by adding oil and running without materials on the working table ensure the flexibility of the transmission system.

6, the cnc woodworking engraving machine is expected to run beyond 10 hours per day. Users of China quality cnc wood router ought to ensure the normal operation of water chiller and clean and water regularly. The shortage of water for water cooling spindle is absolutely not allowed. The regular replacement of water can avoid the high circular water temperature.

7, every time the woodworking engraving work is completed, users of China cnc wood router should pay attention to the cleaning. The platform and drive system must be kept away from dust and the transmission of X, Y, Z three axis should be lubricated by oil regularly.

8, the operators of cnc wood engraving cutting router machine are supposed to wear dust masks and protective glasses to prevent the dust and other harmful stuff form invading into of human body and causing discomfort.

9, a certain dust-proof dust removal device should be equipped with the cnc wood engraving router machine.

Tool broken resons:

1, Processing procedures:

Machining procedure is the instruction of engraving. It contains position instructions and speed instructions, which is the basis of machine tool movement. Therefore, the correct and reasonable machining program of wood cnc carving router will directly ensure the knife tool won’t break.

2, The cnc wood router working table itself

A proper and correct wood cnc engraver router and the current condition of cnc wood router are all important factors for tool broken.

3, Cutting tools

The tool clamping state of cnc wood engraving machine is also an influence factor of tool broken. The uneven tool clamping, or the too long length of tool depth all could cause tool breaking.

4, Materials

Engraving materials of industrial quality cnc wood router are processed objects. If the hardness is uneven or of impurities, it will cause breaking knife.

5, Work piece clamping

If the work piece is not clamped , it will cause the cutter of cnc wood carving router to break.

6, Cutting fluid

It is obvious when machining hard metal by wood cnc mold router machine.

7, The surrounding environment

For example, a vibration source around will affect the processing state, resulting in broken knives. Voltage instability will also lead to abnormal working state of wood cnc router which can also cause a broken knife.

Company information:

iGoldencnc group is one of manufacturing and research and development of the company that focus on CNC engraving machine and cutting machine for many years since 2002. Located in Jinan,shandong province,covers the area of 6000 square meters. Now we have two modern companies and more than 100 people,three sales teams, two product research and development teams, two after-sales service teams. Products exported to Europe,America,Australia,Africa,Asia etc.

Service

1.Engineers available to service machinery overseas. Machine has been adjusted before delivery , operation disk was included.

2.Two year quality guaranty, the machine with main parts(excluding the consumables)shall be changed free of charge when problems happened during the warranty period.

3.Lifetime maintenance free of charge.Free training course at our plant. 24 hours on line service each day, free technical support.

4.We will provide the consumable parts at an agency price when you need replacement.