Views: 25 Author: Site Editor Publish Time: 2022-01-06 Origin: Site

The wooden doors is mainly solid wood, especially composite solid wood. It keeps the advantages of natural wood, and avoids the defects of easy deformation and cracking. Now the traditional manual work has gradually been replaced by wood door design machine. door designing machine, as the new darling of wooden door, has been favored by more and more wooden door manufacturers. wood router is more efficient than manual work, and the defect rate is extremely low.

Wood door design machine is an automated machine that cuts the object to some desired shape. This computer-controlled machine process the wooden materials depending on the design given by the operator. Moreover, This device is handy for both the wood industry and workshops.

A CNC wood router works almost the same as any other CNC machine. A CNC machine or a Computer Numerically Controlled system which uses computer software and CNC controller electronics to drive a mechanical system. Using this setup, it is possible to achieve far better accuracy and precision than a human operator.

A traditional CNC router can move and cut in three directions which are usually referred to at the X, Y, and Z directions. The X-axis is usually the longest of the three running front to back. The Y-axis runs from left to right while the Z-axis runs up and down. Below you can see each axis labeled respectively.

These machines are very efficient in that they work in all three directions in near perfect unison, giving this machine the capability of carving complex shapes.

Detail

Powerful 4.5KW HQD air cooling spindle

Strong and durable transmission

Wood door design machine Features

1.High temperature tempering treatment, welded steel tube T type machine bed and T type gantry, high rigidity, better bearing.

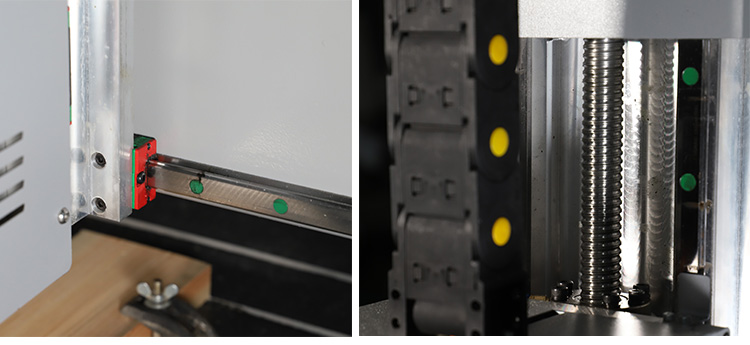

2.Linear guide rail, ensuring the higher precision and long life time.

3.China air or water cooling spindle, more powerful, low noise, not easy to break cutters.

4.Square guide rail transmission for X Y-axis, ball screw transmission for Z-axis, ensuring the machine fast speed and higher precision.

Applications

3D Carving, Acrylic Fabrication, Aluminum Fabrication, Architectural Mill work, Cabinetry, Exhibits and Fixtures, Sign making, Arts and Crafts, Furniture, Musical Instruments and More.

Acrylic, ACM, Copper, Brass, Aluminum, PVC, MDF, Melamine plastic, Foam, Melamine, Phenoic, Plywood, HDPE, Solid Surface, Solid Wood, etc.

Parameter

Description | Parameters |

|---|---|

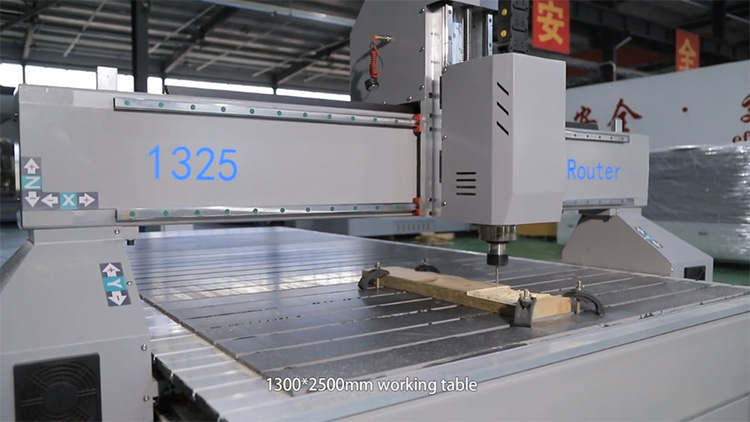

Working area | 1300*2500*200mm |

Spindle | 4.5kw HQD air cooling spindle |

Inverter | Rituo |

Motor | Stepper/Servo |

Motor driver | Stepper/Servo |

Control system | DSP iGoldencnc |

Table | T slot working table |

Guide rail | XYZ Axis Taiwan liner square guide rail |

Ball screw | Z Axis Taiwan TBI ball screw |

Voltage | 380V/50Hz |

| Vacuum pump | Optional |