Views: 111 Author: Site Editor Publish Time: 2021-12-13 Origin: Site

wood edge banding machine is an important process in the manufacturing process of panel furniture. The quality of edge banding directly affects the quality, price and grade of the product. By sealing the edges, the appearance quality of the furniture can be well improved, and the corners of the furniture can be prevented from being damaged during transportation and use, and the veneer layer is lifted or peeled off. At the same time, it can be waterproof, seal the release of harmful gases and reduce deformation, etc. Function, but also beautify the furniture.

1). Multi functional control interface, pneumatic control, no manual tool adjustment, maximum feed speed of 32m / min, easy to use, no need for special post skill training.

2). Super cost performance

The equipment can meet the basic needs of small workshop edge sealing, and the price is very close to the people. It is suitable for personal or small workshops with low requirements, and can meet the simple personal DIY needs, while the equipment cost threshold is very low, which is easier to start.

3).Exquisite electricity saving

The equipment covers an area of only 3.7m², which is especially suitable for small workshops with tight production space. The total power of the equipment is only 9.5kw, with ultra-low power consumption and lower power consumption pressure.

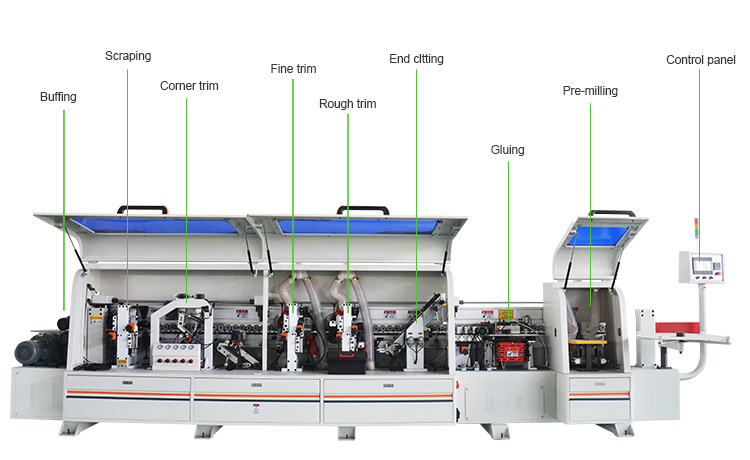

Features of wood edge banding machine:

1:Flexible, advantages of high performance, easy debugging, convenient in maintenance and easy to operate.

2: high quality electric components and transmitting component make machines fuction more steady.

3: Full-close safety shield,more human operation.

4.energy-saving,enduring.

5.Stable performance.

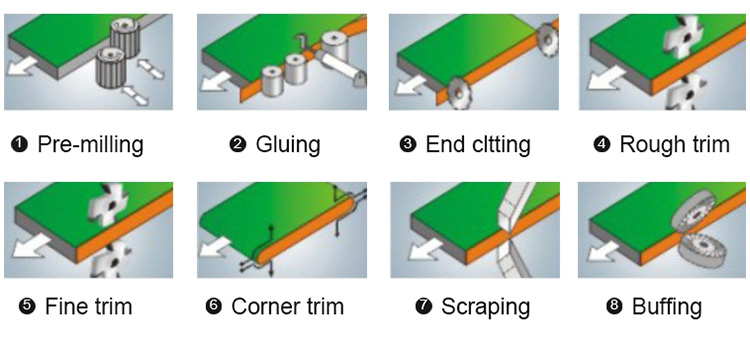

Feeding Belt : Made of special material which guarantees long lasting sturdiness & stability. Synchronous teeth of belt & pinion gives high traction & vibration free movement with optimal panel holding

Gluing, Banding & Edge Cutting : Edges in rolls are loaded automatically and cut precisely to size with a cutter

End Cutting : Pneumatically operated End cutting unit has solid cutter to guarantee a clean, precision cut on the front and rear edges of the panel

Edge Fine Trimming :

A) Compact and powerful high frequency motors guarantees best finish on top and bottom edges.

B) Unit has copiers which are bearing mounted to ensure smooth panel feed.

C) Very easy precision adjustment of trimming cutters by position indicators.

Buffing : Unit ensure surfaces to give a perfect polishing effect of the edges

Control Panel : Easy accessible user friendly control panel positioned at in-feed, for easy and quick operation

Radius Trim : For Chamfering of the Panel Corner, manually (Radius function Applicable For Model J-4300R.in Only)

We are a company integrating manufacturing and sales of CNC routers, laser engraving machines, laser cutting machines, plasma cutting machines, cutting plotters, etc. The main configuration all adopt top parts imported from Italy, Japan, Germany, etc.We adopt international advanced producing technologies to improve our products. Our products are widely used in advertising, woodworking, artworks, model, electric, CAD/CAM industry models, clothing, package printing, marking, laser sealing and so on.